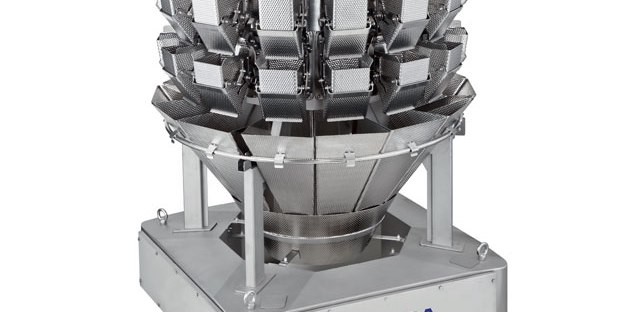

A Multi-head weigher is one of the fastest and most accurate weighing machine widely used in weighing of products in the category of foods (vegetables, all kinds of meat, granules-tea, coffee, rice, e.t.c.) in both manufacturing and non-manufacturing industries around the world. Its accuracy and precision has facilitated its widespread use. The product is usually fed on top of the Multi-head weigher and is distributed to the heads commonly known as feed plates. In reality, the distribution of the products to the plates is usually by vibration or gravity. Eventually, specified weights of your products are released at the bottom of the Multi-head weigher plates.

While investing in a Multi-head Weigher can be expensive in the beginning, you can absolutely be certain of long-term benefits in the future. If you are a manufacturing company, a Multi-head Weigher will help you in bag filling whether in small or big bags, mixing of different product components especially a combination of product that contains a cheap one and an expensive one and finally, it will assist in the introduction of products into trays.

Do you want to see a high return on investment for your company? Do you do bulk weighing for your product? Are Speed and Accuracy of essence in your company? If so, you definitely need a weigher for that purpose. The following are the 7 reasons why you need a Multi-head Weigher for your Weighing and Packaging Solutions.

High Speed

As compared to man labour, a Multi-head Weigher is fast and versatile. Speed is one of the factors that companies must take into consideration before purchasing a Weigher. Always, a customer would go for the fastest Weigher of all. A multi-head Weigher will weigh up to a speed of 150 WPM. Depending on the weight, you can pack up 90 packets per minute.

Accuracy

A Multi-head Weigher has been able to prove accuracy when weighing. This ensures low or non-existent giveaways.

Gentle Handling of your Product

If your product is prone to breakage or deformation due to mishandling, then, automated weighing is preferred than man labor. This will ensure efficiency in handling of your product and less or no breakage.

Easy Comply with KEBS (Kenya Bureau of Standards) and Validation

Appropriate for different kinds of food products, a Multi-head Weigher is fully constructed from stainless steel thus the best machines that comply with KEBS on handling a wide range of food products. It can also work in different working environments and still be safe for food packaging.

Health, Cleanliness and Sanitary

Every company makes efforts to ensure health compliance is achieved in the shortest time possible. It is the very first goal of an industry, especially the ones dealing with food related products to ensure health while at the same time reducing the cleaning costs. With a Multi-head Weigher for your packaging, cleaning is fast and can go on even during production thus there is less contamination of your product. This eventually ensures cleanliness of your product.

High Labour Efficiency

If your products to be packaged are always accumulated just before weighing, you need to eliminate your man labour and opt for automated Weighing. This will reduce labour costs as well as weighing time by days and at a time. Fast and efficiency weighing of your product is guaranteed accompanied with high saving of labour costs.

Cost Reduction

There is absolutely no doubt that automated weighing reduces labor costs in the short-run and more revenue in the end for many companies. Aiming for a long-term cost reduction, a Multi-head Weigher will always offer high quality weighing, speed and accuracy.

Interestingly, do you know that a Multi-head Weigher can be integrated with FFS, Check Weigher and X-ray Inspection Systems? Yes, these are important for a serious producer who would like to comply with weight legislation. A Check Weigher is normally put at the end of the Multi-head Weigher and ensures the packed weight of a product is within the specified limits as required by the legislation. On the other hand, an X-ray Inspection System uses X-rays to detect unfamiliar features of a product that cannot be viewed by a naked eye. So, if you are on a meat processing industry and you want to detect bone fragments on packed meat, then, an X-ray Inspection System is the perfect machine for that.

The big question is, are you ready to deploy a Multi-head Weigher in your industry? I invite you to visit or contact Allwin Packaging International Limited. Allwin is the largest supplier of Packaging Machines in East and Central Africa that offers different kinds of packaging machines and services. These include installation and commissioning of new machines, servicing of the machines, troubleshooting and repair of the machines in case of a breakdown. Allwin also supplies you with spare parts and consumables for the machines. It is the only certified distributor of ISHIDA Packaging Machines in this region. With Allwin, you are guaranteed of all Packaging solutions that work for you!